Manufacturing Excellence

Swiss technology meets traditional expertise in our state-of-the-art facility

Swiss technology meets traditional expertise in our state-of-the-art facility

Every grain goes through 6 stages of meticulous processing to ensure premium quality

We source premium quality paddy directly from trusted farmers in Basmati-growing regions. Each batch undergoes rigorous testing.

Advanced cleaning machines remove dust, chaff, and foreign materials. Destoners eliminate stones and metals with precision.

Modern hullers remove the outer husk. Polishing machines give rice a shiny appearance while retaining essential nutrients.

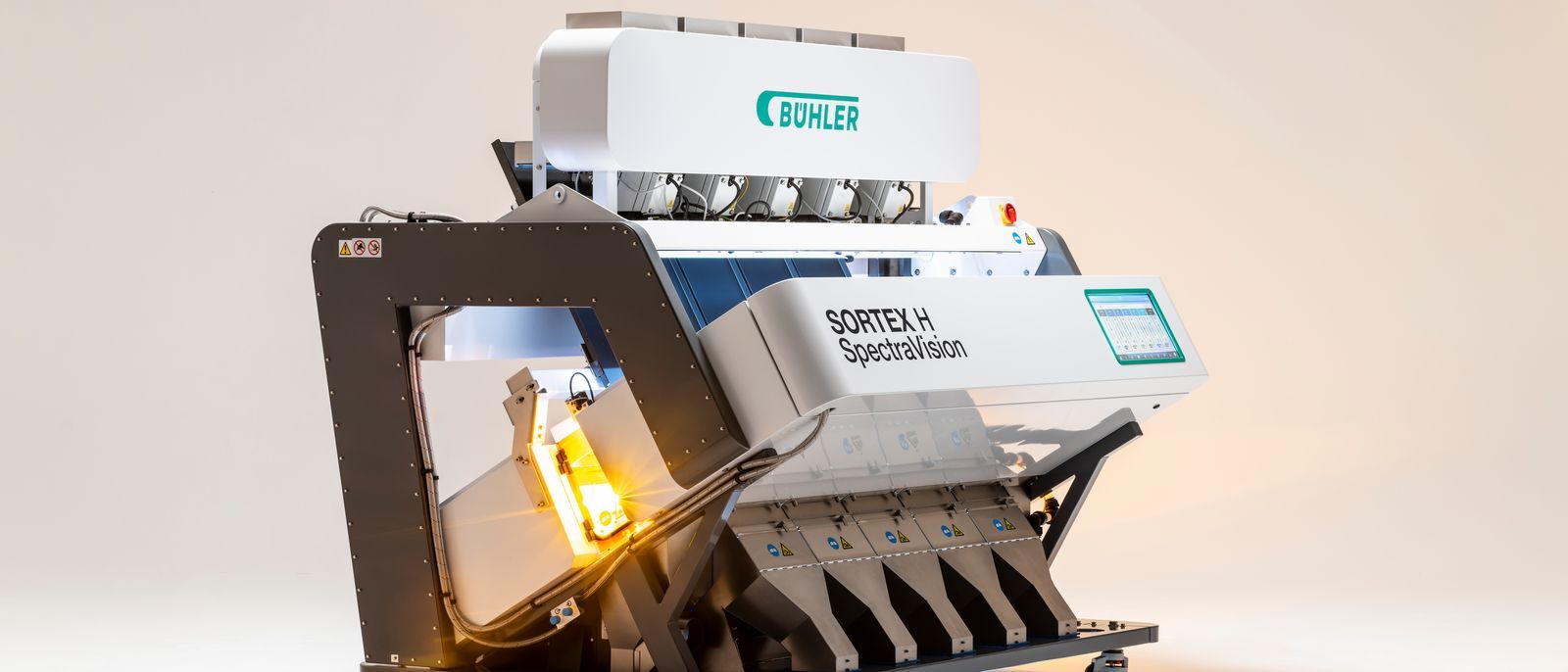

Our Swiss Buhler Sortex optical sorter uses AI and high-speed cameras to detect and remove defective grains with 99.9% accuracy.

Rice is graded by size and quality. Color sorters remove discolored grains, ensuring only perfect grains proceed to packaging.

Rice is packaged in food-grade, airtight bags. Climate-controlled warehouses maintain optimal temperature and humidity for storage.

The heart of our quality control process. This Swiss-engineered machine represents the pinnacle of optical sorting technology, using artificial intelligence and high-resolution cameras to inspect every grain at microscopic levels.

4,000+ images per second analysis

Deep learning algorithms for defect detection

99.9% defect removal accuracy

Processes 8 tons per hour

State-of-the-art milling equipment for gentle processing that preserves grain integrity and nutritional value.

Advanced color sorting technology to ensure uniform color and remove any discolored grains.

Fully automated packaging lines that ensure precise weight measurements and hygienic sealing.

Moisture, purity, and quality analysis

Length, width, and elongation testing

Traditional aroma evaluation

Quality certification before dispatch

See how our advanced technology creates superior quality rice

Schedule Factory Visit